- WOOD

- TECHNOLOGY AND INNOVATION

Trough innovations we lead the way

Through investments in new technology and constant work to develop innovative products, we aim to find new solutions to both today's and tomorrow's problems. Always with the customer's needs at the center.

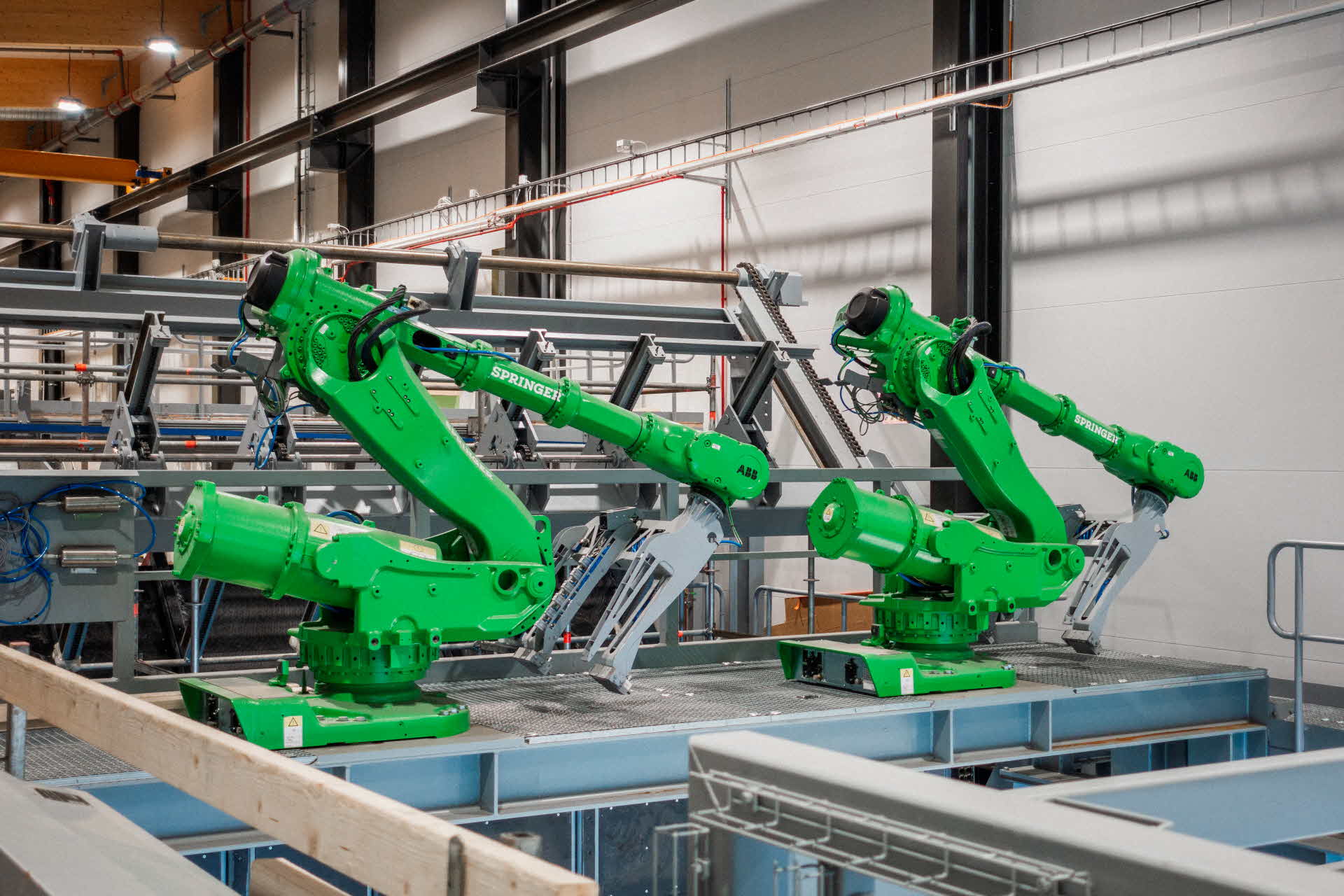

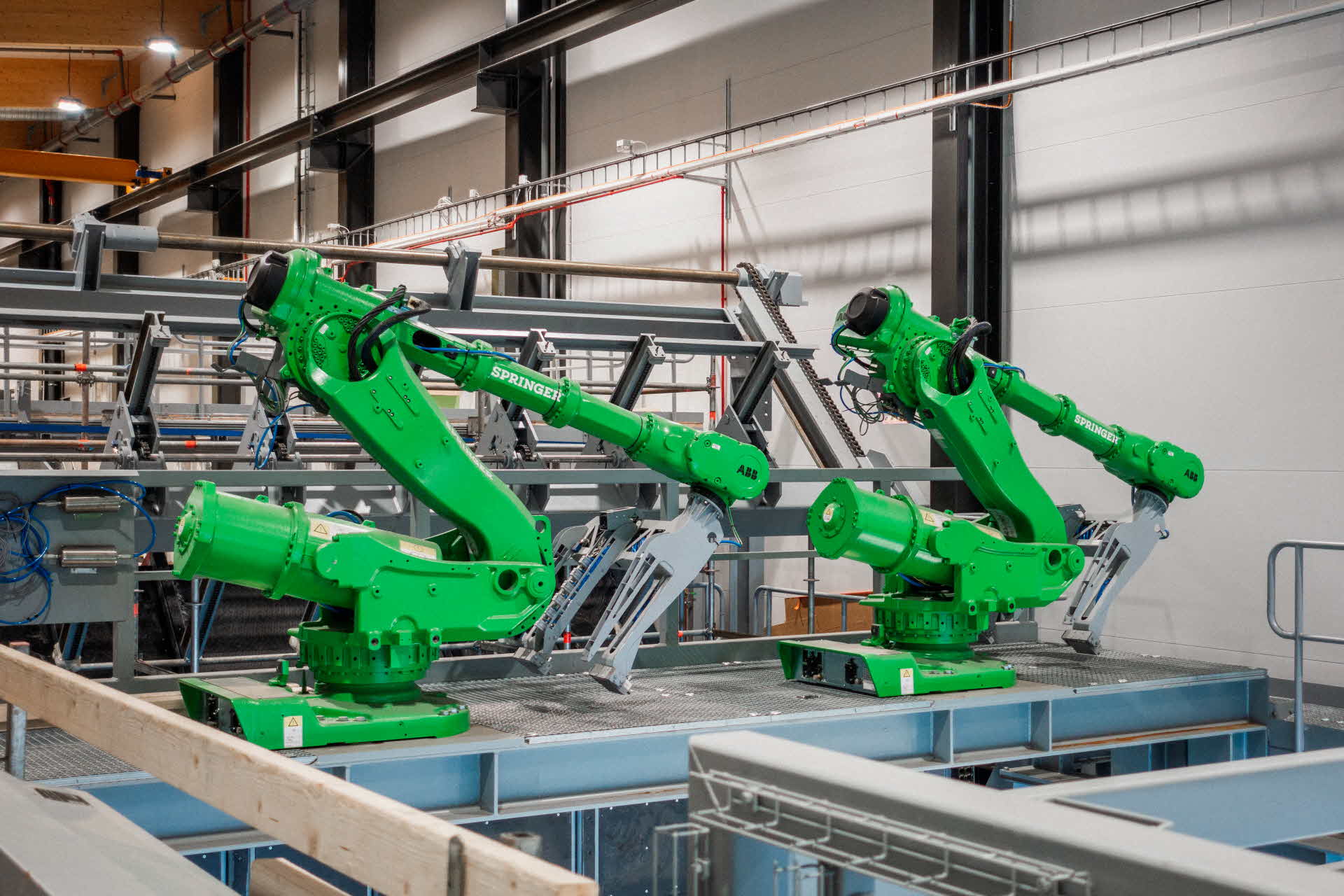

A state-of-the-art dry sorting facility

At our sawmill in Bollsta, we are currently building the world's safest and most productive dry sorting. A state-of-the-art facility full of new technology that cannot be found in any other dry sorting plant in the world. With the facility in operation, the Bollsta sawmill will be able to increase its total capacity to approximately 700,000 cubic meters per year.

Lodgepole pine

After experimenting, testing and building up our knowledge bank waiting of larger volumes of mature lodgepole pine timber, we’re now in the process of gradually starting to scale up the production of wood products based of Lodgepole pine in the coming years.

Pellets production in Rundvik

Right now we are building a pellet plant at Rundvik's sawmill, which will make it possible for us to process all of the chippings that are currently generated from the planer. Instead of being transported further for processing elsewhere we’ll now be able to turn it into fossil-free fuel directly on site.

Upgraded planing mill in Stugun

As part of the company's investment in developing the sale of further processed wood products to the building merchants in Scandinavia, We’re now investing approximately SEK 55 million in our planning mill in Stugun. An investment that further strengthens our own value chain and operations locally in Jämtland.

Wood packaging made with 70% recycled plastic

We’ve developed tomorrow’s digital tool in order to further enhance our customer service. Images, marketing texts, article data, certificates and documents. Everything that can ever be needed neatly structured in one user-friendly digital platform.

Impregnated by nature itself

The water-repellent, rot-resistant properties of heartwood make it ideal for manufacturing wood products for outdoor use. But what is heartwood and how is it formed?