By placing brush mats on strip roads at the harvesting site, logs can be harvested and extracted efficiently without causing any damage to soil or water. This also improves the work environment for the machine operators.

The SED method protects soil and water

It is vital that our felling operations does not cause any damage to soil or water. Therefore we work with our own SED (Swedish acronym for “Gentle Effective Logging”) method. This method helps to reduce wheel rutting and also to improve work efficiency.

The SED method involves planning how the machines will drive, placing brush from the felled trees on the roads that are used most and building crossings, to enable efficient harvesting and extraction of the logs without causing any damage to soil or water.

Avoid difficult sections

Planning is a key element of the SED method. By choosing the best routes for the trails on the site, we can avoid difficult sections and minimize the areas driven on by the forwarder. The harvester also hauls logs from areas with weak bearing capacity to areas with high bearing capacity, where the forwarder is working. Another important point is that the harvester enters GPS coordinates in the machine’s computer, so that the forwarder receives clear track markings to show the route it should drive.

On slopes, mires or areas where turning around is not possible, the forwarder always reverses in. Then the operator can load the logs while driving towards firm ground. That means that the lightest load is distributed over the weakest soil, reducing the risk of wheel rutting or getting bogged down.

Brush mats protect the soil

Another key element of the SED method is to build appropriate crossings over streams and watercourses, and to place brush mats on the strip roads. We use also brush mats to strengthen weak sections on other parts of the site.

Clear information and good communication between the site planner, production supervisor and harvester and forwarder operators are also important. Everyone must be engaged and work together for the best results.

The SED method is used for both final felling and thinning, and has many benefits. In addition to avoiding wheel rutting, we can also harvest more sites at any time of year. The SED method also makes harvesting more efficient. The machinery can cause less impact and work faster when brush mats are placed on the strip roads. Using brush mats on strip roads makes them smooth and sustainable, enabling more efficient driving. The brush mats also improve the work environment for the drivers, because driving is more comfortable.

By planning in advance, you can ensure that the logs are stacked in dry sections with high bearing capacity that the forwarder can reach without any problems.

The SED method focuses on five areas to avoid wheel rutting:

- Landing

Wheel rutting usually occurs close to the landing, where most of the logs are stacked. Landings should therefore be planned carefully, to ensure they have high bearing capacity. - Haul road

The haul road connects the landing with the entrance to the site’s main hoal road. The closest road with bearing capacity is always chosen as the hoal road. - Main hoal road

Most of the logs will be transported along the main hoal road. It proceeds from a landing or a hoal road and is always covered with brush mats. - Problem management

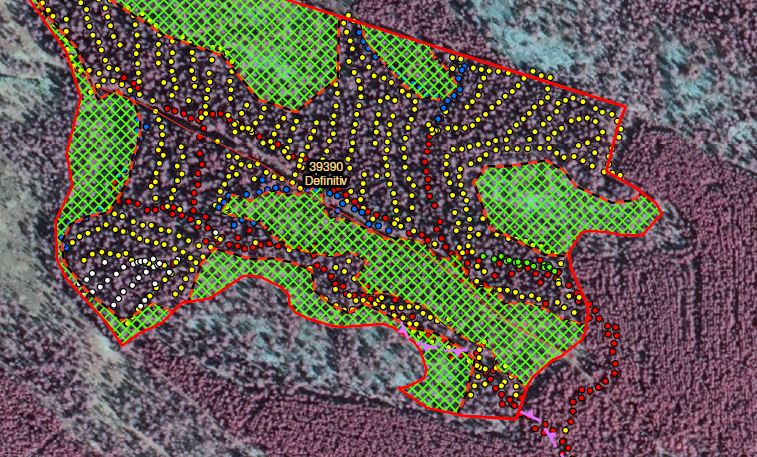

Dealing with problems, having clear information and good communication between all involved parties are important for both planning and felling on the site. - GPS log coordinates

The harvester operator uses the machine’s GPS logging to mark the type of strip road that will be made. The different colors of the GPS coordinates indicate what type of road it is, and show the forwarder operator where to drive.

How SCA applies the SED method

Brush mats on strip roads

Maps to show wet sections

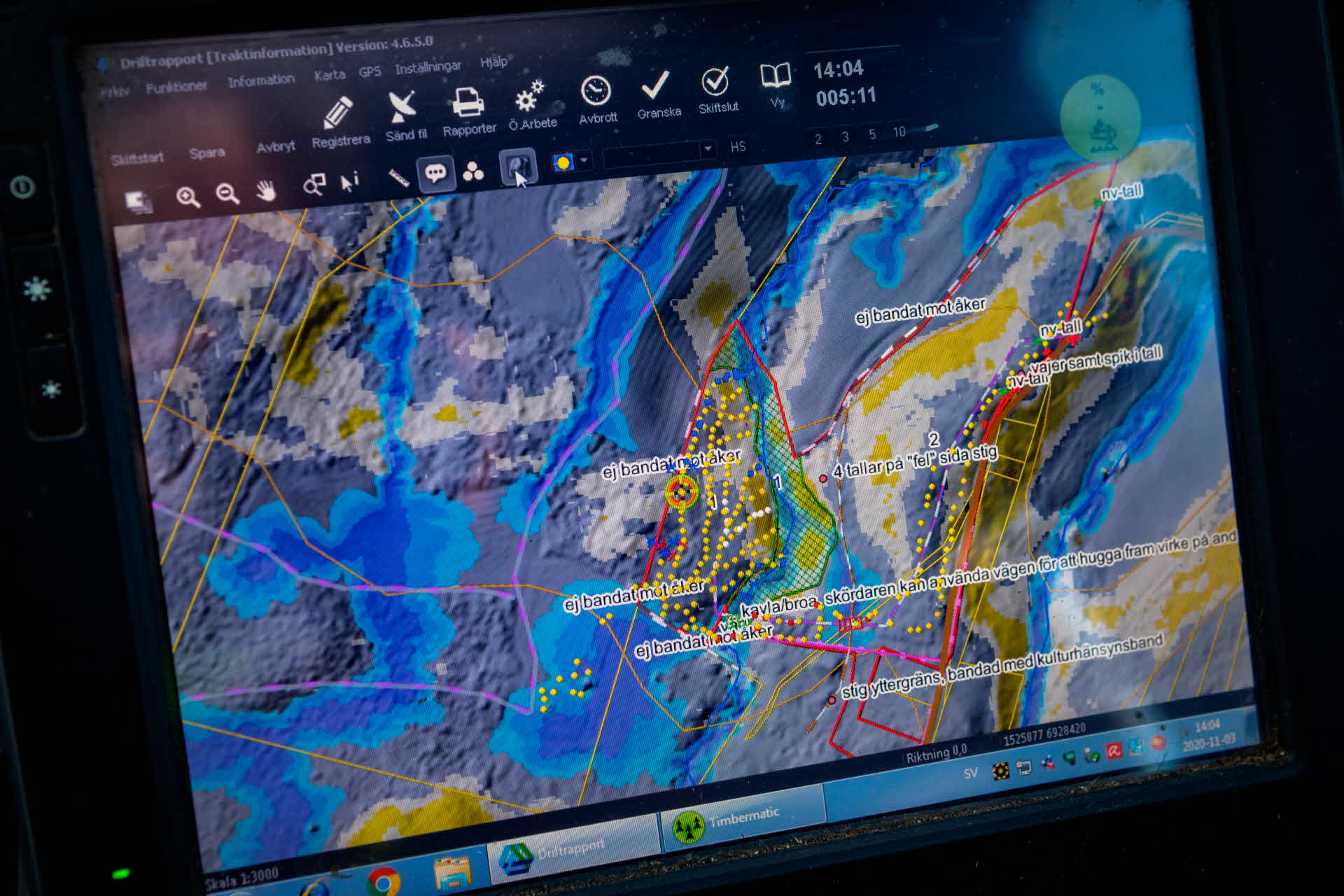

Due to the wealth of information on the map in the harvester’s computer, the machine operator can see where there are wet sections in the area, for example, and avoid driving there.

GPS coordinates show the way

The harvester operator enters GPS coordinates in the machine’s computer, providing clear track marks for the forwarder and show how they should drive to avoid wheel rutting.

Planned driving

The harvester operator has felled some spruce trees close to the stream and stacked the logs further up to make it easier for the forwarder to reach them. That means that the forwarder will never have to drive on the sensitive area around the stream.

Appropriate crossings

A key element of the SED method is to build appropriate crossings over streams and watercourses. Careful planning is carried out here to determine the best method for building the watercourse crossing for the forwarder.

Log bridge

It is important to protect both the actual watercourse and the surrounding soil. Here, the harvesting team has built a bridge using logs and brush from the harvested trees.