Our history

Throughout history, SCA has built a well-invested value chain that maximizes the value of each tree. SCA was established in 1929, but the forest had been of great importance to the region long before that.

The importance of the forest for industrialization

Already in the 17th century, when forest farmers began producing tar from wood, the forest in Sweden gained significant value. This was followed by opportunities to extract charcoal, smelt iron ore, and establish sawmills. The forest became the foundation for development in Sweden.

The establishment of SCA

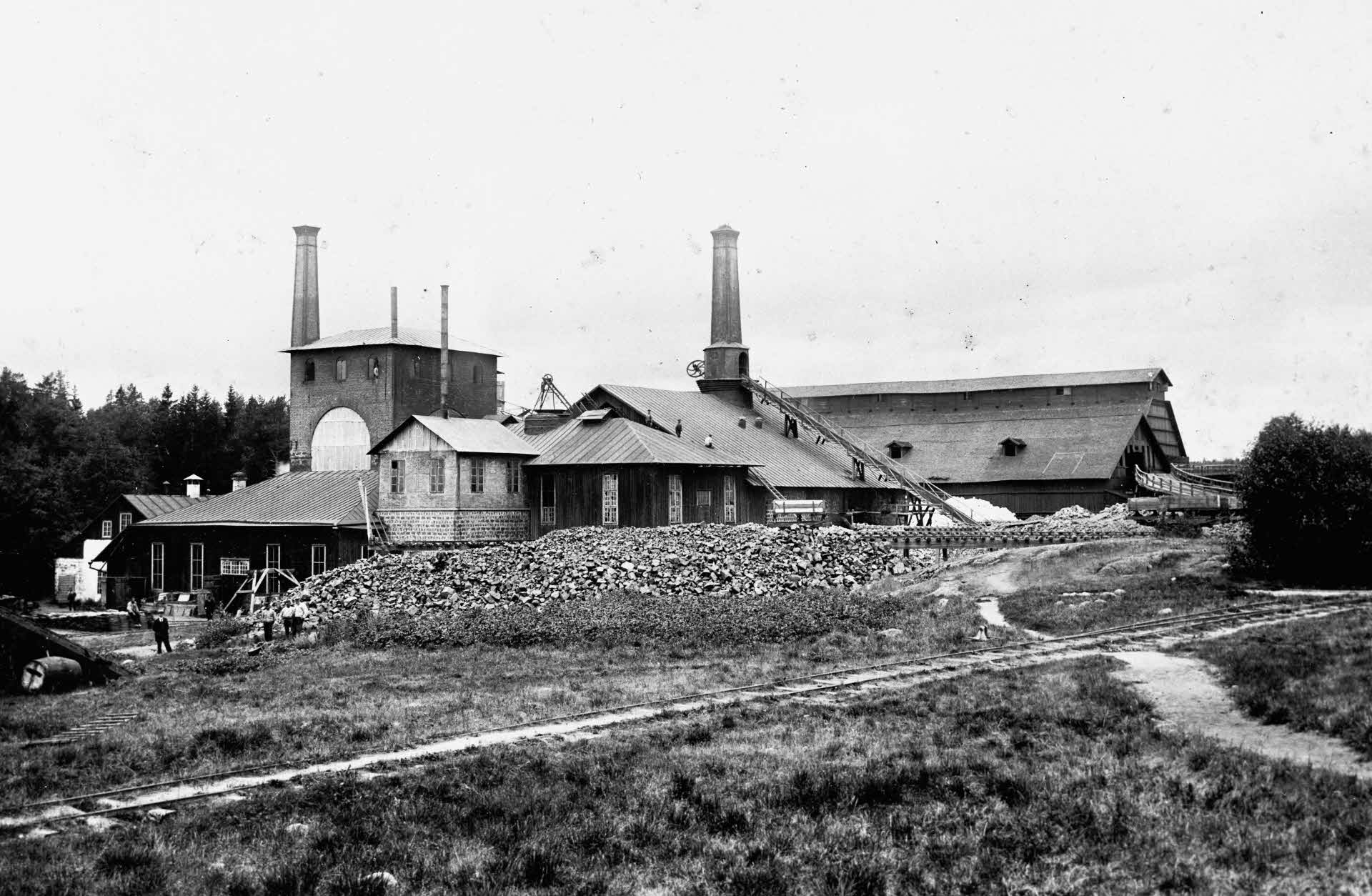

The Galtström Ironworks was founded in 1673

SCA's oldest predecessor, the Galtström Ironworks, was founded in 1673 and operated until 1916. After the closure of the ironworks, SCA took over the management of the site and the associated housing. Today, Galtström Ironworks is a popular tourist destination, and parts of the facility are used by SCA for conference activities.

1849 - Sweden's first commercial steam-powered sawmill

In 1929, Ivar Kreuger founded SCA

In 1931, the Östrand pulp mill began operations with a capacity of 100,000 tons of pulp, making the facility one of the largest producers of bleached softwood sulfate pulp at the time. The decision, made by SCA's board, was the first investment decision taken after the company's formation.

In 1931, the central laboratory in Östrand was inaugurated

As the Östrand sulfate mill was constructed, a central laboratory was also established on site. The laboratory conducted pulp testing and various development projects. Over time, the scope of development work grew, creating the need for a research facility of a different scale and with greater resources than what was available at Östrand. In 1945, the research laboratory in Kubikenborg was commissioned. In the year 2000, SCA relocated its research operations, the R&D Centre, to new premises adjacent to Mid Sweden University’s campus. Today, the university and SCA collaborate on a range of research projects.

Kreuger's death and the subsequent break-up of his company Kreuger & Toll in 1932, eventually led to Svenska Handelsbanken assuming full control of SCA.

In 1950, Handelsbanken listed SCA on the Stockholm Stock Exchange.

In 1961, SCA started its first kraftliner machine in Munksund and this marked the starting point for SCA's packaging business. To secure the market for liner, SCA entered the corrugated cardboard market by acquiring several facilities in Europe.

In 1967, Paper Machine 4 (PM 4) at Ortviken was brought into operation, as part of a focused effort on further processing through increased paper production.

In 1967, the ship M/s Tunadal was launched, followed by the commissioning of two more vessels, all part of investments made in the logistics sector during the 1960s. With its own logistics organization, SCA could now ensure secure transportation solutions and mitigate cost increases.

In 1975, SCA's sulfate pulp mill in Obbola was converted into a kraftliner mill.

The acquisition of Mölnlycke

SCA took the first step towards becoming a consumer goods company with the acquisition of the Swedish personal care company Mölnlycke. This acquisition boosted the Group's sales by 40 % and resulted in tissue, diapers, feminine hygiene and incontinence products being included in the product portfolio.

In the 1980s, SCA made several acquisitions, expanding within the packaging, hygiene, and printing paper segments.

In 1995, SCA acquired a majority stake in the German company Papierwerke Waldhof Aschaffenburg (PWA), thereby becoming Europe’s largest forest-based hygiene products company.

In 2003, SCA acquired Graninge’s forests and sawmills, resulting in an increase of approximately 400,000 hectares of forest holdings. The acquisition included several sawmills, of which Bollsta and Rundvik are still in operation under SCA’s ownership. Since 2019, SCA has also expanded its forest holdings outside of Sweden, with the purchase of the first forest properties in the Baltics.

In 2012, SCA divested parts of its packaging business through a sale to DS Smith, enabling increased growth in its hygiene business. The liner mills in Obbola and Munksund remained under SCA’s ownership.

In 2013, SCA and the Norwegian energy company Statkraft inaugurated their first jointly-owned wind farm, marking the beginning of SCA’s wind power initiative.

In 2013, SCA became the majority owner of the Chinese tissue company Vinda. The following year, the partnership was strengthened when SCA transferred its entire hygiene business in China, Hong Kong, and Macau to Vinda.

In 2014, SCA participated in the Volvo Ocean Race with an all-female crew, sailing around the world. SCA’s participation provided a unique platform to increase brand awareness and strengthen the connection between SCA and its customer and consumer brands. The team finished in 6th place in the race.

In 2017, SCA was divided into two listed companies.

At SCA's Annual General Meeting in 2017, the company's shareholders voted in favor of the Board of Director's proposal to split the Group into two listed companies; the forest products company SCA and the hygiene and health company Essity.

In connection with the split, SCA’s headquarters were moved back to Sundsvall, while Essity's headquarters are located in Stockholm.

In 2019 the new Östrand mill was inaugurated

The new mill at Östrand was inaugurated in 2019, and the investment doubled the mill's capacity to 900,000 tons per year, making it the largest production line for bleached softwood sulfate pulp in the world.

In 2021 publication paper production is discontinued

In 2020, SCA decided to shut down the production of printing paper at the Ortviken paper mill due to a shrinking market. At the same time, a decision was made to invest SEK 1.45 billion in the production of chemically pre-treated thermomechanical pulp (CTMP) at Ortviken. In 2021, all three paper machines at Ortviken were shut down, and the production of printing paper ceased.

In 2021 the new paper machine in Obbola was inaugurated

In 2019, SCA decided to invest SEK 7.5 billion in a new paper machine for the production of kraftliner at Obbola paper mill. The facility was inaugurated in 2021, featuring the world’s largest machine for kraftliner and a significantly increased production capacity.

In 2023, the new CTMP facility was inaugurated

In 2020, SCA decided to build a new pulp mill for chemical thermomechanical pulp (CTMP) at Ortviken, transferring the previous production from Östrand to Ortviken. The facility was completed in 2023 with the goal of increasing CTMP production from approximately 90,000 tons per year to 300,000 tons per year. This allows an increasing production of kraft pulp at Östrand Pulp mill.

In 2023, SCA’s new planing mill was inaugurated

In 2023, the new planing mill at the Bollsta sawmill was inaugurated. As part of the investment, a new CT scanner was installed, enabling Bollsta sawmill to use digital measurement, computed tomography, image analysis and artificial intelligence to monitor each product as it passes through the sawmill and harness the potential value of each individual log.

In 2024, biorefinery in Gothenburg was inaugurated

In 2021, SCA decided, together with St1, to produce biofuels, using materials such as tall oil from the forest industry, at the biorefinery in Gothenburg. The biorefinery was inaugurated in 2024. And at the same time, SCA is preparing a larger investment in biofuels at the Östrand pulp mill in Sundsvall. Land development is currently underway near the industrial site to make space for a potential future facility.

In 2024, SCA's new container port was inaugurated

In 2024, both SCA's container port and Sundsvall's logistics park were inaugurated. The investment in the logistics park involved Sundsvall Municipality building a new intermodal terminal, allowing goods to be efficiently transferred between ships, rail, and trucks. At the same time, SCA constructed a new high-capacity container port. The Swedish Transport Administration is also making several investments in the railway infrastructure around Sundsvall. This joint investment in sustainable transportation is a key component of the green transition in northern Sweden.

The story continues

Stay updated with the latest developments at SCA.